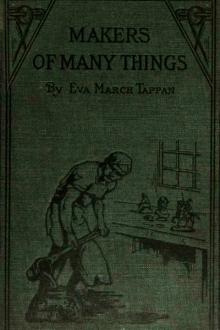

Makers of Many Things

Makers of Many Things

Industrial Readers, Book III

The little friction match -- About india rubber -- "Kid" gloves -- How rags and trees become paper -- How books are made -- From goose quill to fountain pens and lead pencils -- The dishes on our tables -- How the wheels of a watch go around -- The making of shoes -- In the cotton mill -- Silkworms and their work.

Book Excerpt

th used for lining and stays. Rubber and rubber-lined cloth go to the cutting-room, where all the different parts of the shoes are cut out. They are then put together and varnished. While still on the last, they are dipped into a tank of varnish and vulcanized--a very simple matter now that Goodyear has shown us how, for they are merely left in large, thoroughly heated ovens for eight or ten hours. The rubber shoe or boot is now elastic, strong, waterproof, ready for any temperature, and so firmly cemented together with rubber cement that it is practically all in one piece.

During the last few years there have been frequent calls from various charities for old rubber overshoes, pieces of rubber hose, etc. These are of considerable value in rubber manufacturing. They are run through a machine which tears them to shreds, then through a sort of fanning-mill which blows away the bits of lining. Tiny pieces of iron may be present from nails or rivets; but these are easily removed by magnets. This "reclaimed

FREE EBOOKS AND DEALS

(view all)Popular books in Young Readers, Non-fiction, Fiction and Literature

Readers reviews

0.0

LoginSign up

Be the first to review this book

Free Download

Free Download